With the global energy shortage, energy conservation in industrial plants, as the main body of industrial energy consumption, is imperative. The energy consumption of the plant and the insulation system of the plant are directly related, the advantages and disadvantages of the plant insulation system are also the key indicators of the factory environment measurement, the cooling of the plant is a comprehensive problem, to solve it needs to be the right medicine, first of all, to find the key factors affecting the temperature of the plant, focus on its governance, and then choose the appropriate method to target other relative secondary factors to deal with, in order to achieve a good indoor environment and its highest cost performance.

In order to calm the "people's hearts", some high temperature subsidies, some pot mung bean soup, eat watermelon, etc., but the symptoms are not cured, although the people's hearts are stabilized for a while, but it does affect the production efficiency, not only that, some overheated environment will affect product quality, such as batteries and other products that are not resistant to high temperatures, high temperatures to the enterprise 5 major impacts! 1, high temperature leads to high workshop temperature, employees work easy to sweat, poor working state. 2, the workshop area is large, the personnel is dense, the machine heat dissipation, resulting in the workshop air circulation, stuffy. 3. Low employee work efficiency, affecting production progress and product quality. 4, 80.90 after the workshop environment requirements are high, the workshop is too hot, new employees are reluctant to come in, old employees can not stay. 5. The poor workshop environment affects the overall image of the company, affects the company's customer inspection and fire inspection.

Requirements analysis

Solution Description:

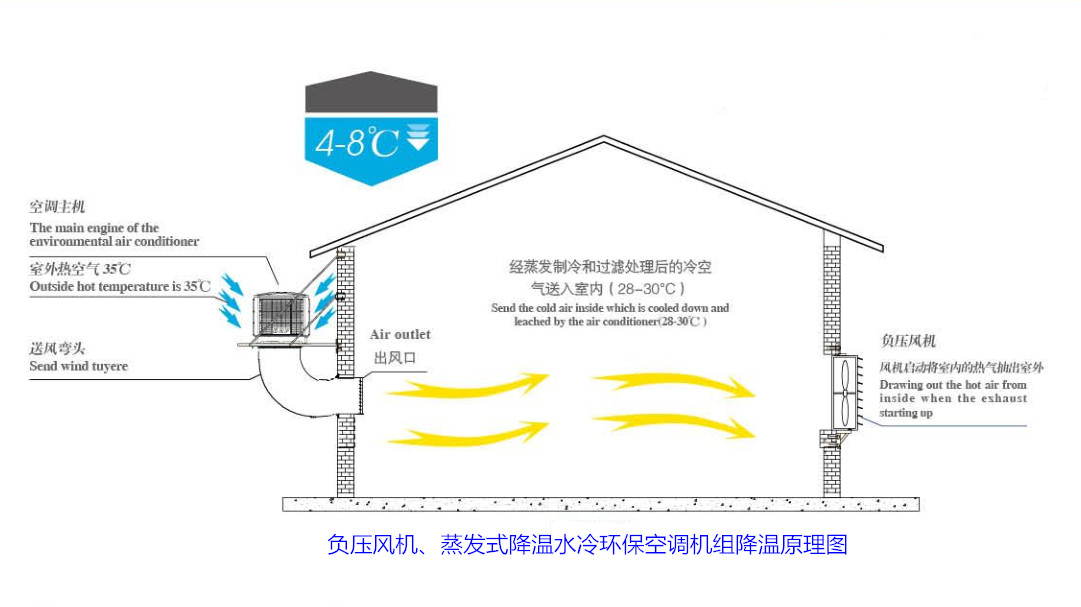

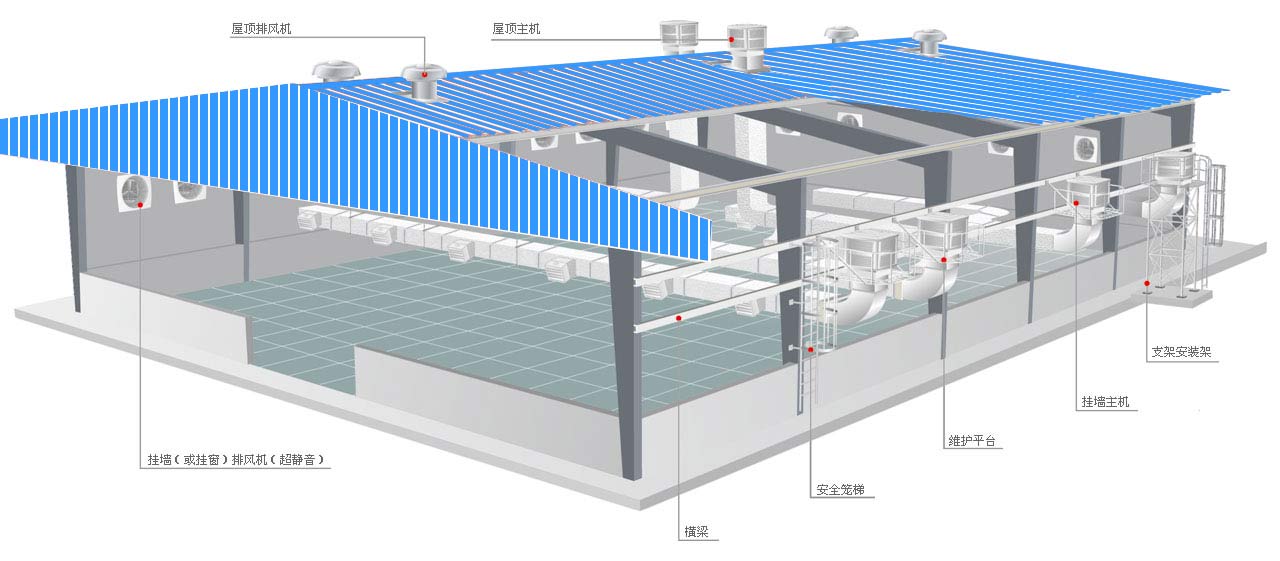

Evaporative cooling environmental protection air conditioning unit cooling principle: evaporative cooling environmental protection air conditioning positive pressure air supply ventilation cooling system, is on the roof or side wall of the plant or a location inside the workshop (as far as possible to choose the side wall hanging, according to the actual environment of the scene) to install water-cooled environmental protection air conditioning host connected to the air supply pipe, the external natural wind through the evaporative cooling water cooling environmental protection air conditioning unit system generated by the negative pressure so that the external air flows through the porous moist water curtain paper surface formed by the evaporation of the water film vapor absorption heat absorption instantaneous cooling at the same time filter the dust in the air, A large amount of heat is heat exchanged and converted to force the air entering the room to be reduced by 5-10 ° C, and the cool air will be continuously blown into the interior of the workshop through the air supply pipe, thus creating a comfortable, cool and fresh working environment and the comfortable feeling of the breeze in the workshop.

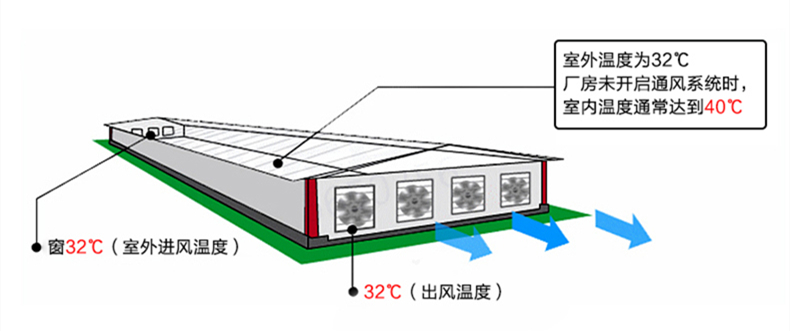

Solution three: the use of negative pressure fan ventilation and heat exhaust ventilation system scheme

Solution Description:

Negative pressure fan ventilation heat exhaust ventilation cooling principle: negative pressure fan outward discharge air so that the indoor air pressure drops, indoor air becomes thinner, forming a negative pressure area, air due to air pressure difference compensation into the room. In the practical application of industrial plants, the negative pressure fan is centrally installed on one side of the plant, the air inlet is on the other side of the plant building, and the air is convected from the air inlet to the negative pressure fan to form a convection blower. In this process, the doors and windows near the negative pressure fan remain closed, forcing air to flow into the workshop by the door and window on the side of the air intake. The air is lined up and orderly flows from the air intake to the workshop, flows through the workshop, and is discharged from the workshop by the negative pressure fan. The ventilation is thorough and efficient, with a ventilation rate of up to 99%. Through specific engineering design, according to the need to design the ventilation speed and wind speed, any high heat, harmful gases, dust smoke can be quickly discharged out of the workshop, any poor ventilation problems can be completely solved at one time. Ventilation can be achieved within a few seconds of turning on the fan.

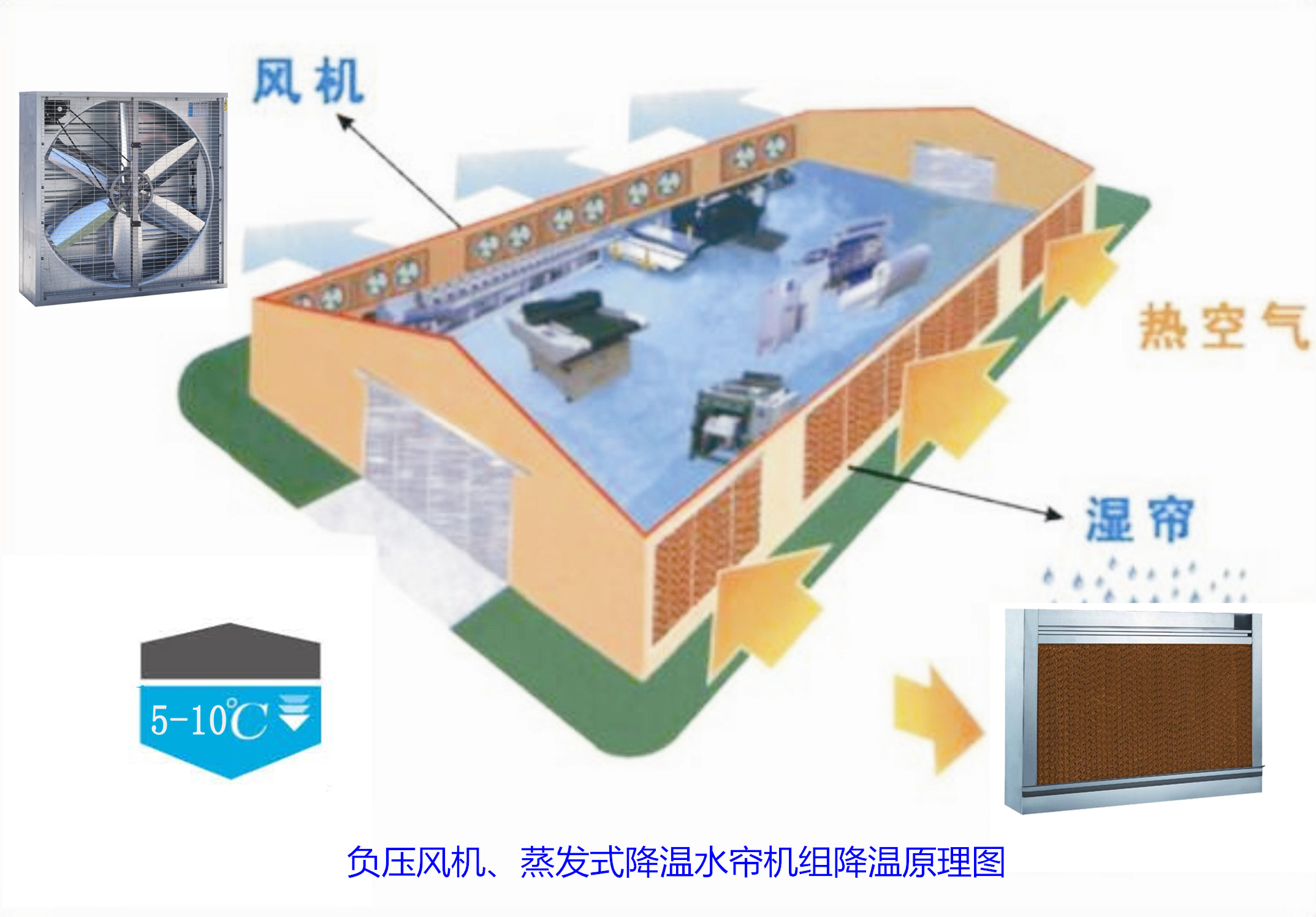

Solution four: the use of negative pressure fan + evaporation cooling water curtain negative pressure ventilation cooling system scheme

Solution description:

negative pressure fan + evaporation cooling water curtain unit system cooling principle: fan water curtain type negative pressure ventilation cooling system, is to install a large air volume negative pressure fan at one end of the plant, in the fan installation opposite the installation of evaporative cooling water curtain unit and related accessories, the negative pressure fan will be the plant inside the sweltering air, odor, smoke forced outward pumping, workshop ventilation capacity maintained at 70 ~ 85 times / hour design , the formation of strong negative pressure in the workshop (the workshop needs to maintain more than 85% sealed), the external natural wind through the negative pressure exhaust fan exhaust system generated by the negative pressure so that the external air flows through a large area of porous moist water curtain paper surface formed by the evaporation of the water film instant cooling at the same time filter the dust in the air, a large amount of heat exchange conversion treatment to force the air into the room to reduce 5-10 ° C, cool air will continue to blow into the inside of the workshop, and then create a comfortable, cool, Fresh working environment and the comfort of the workshop with a breeze.

Solution five: adopt industrial large fan positive pressure supply air cooling scheme

Solution Description:

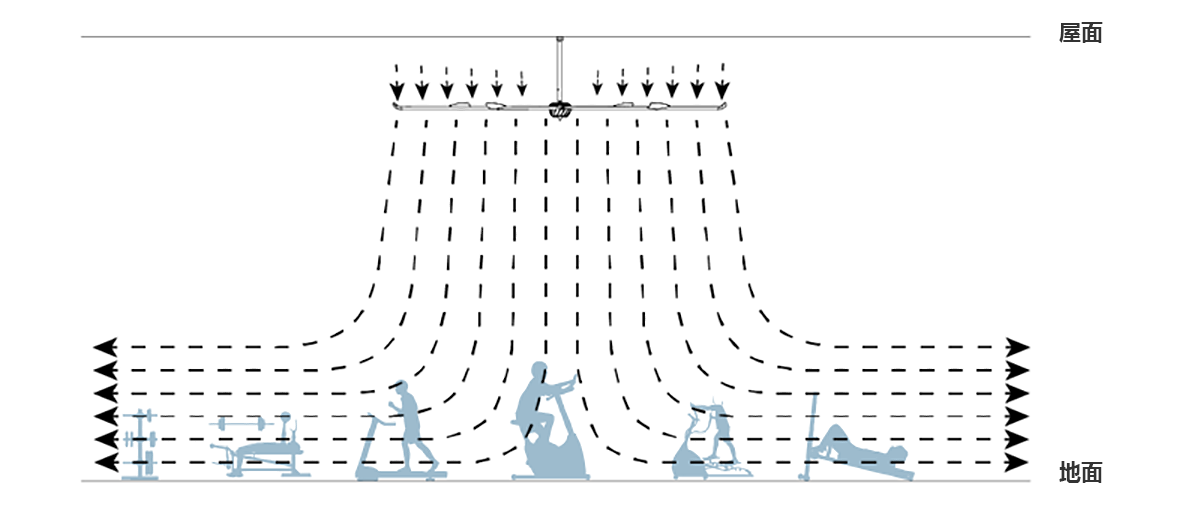

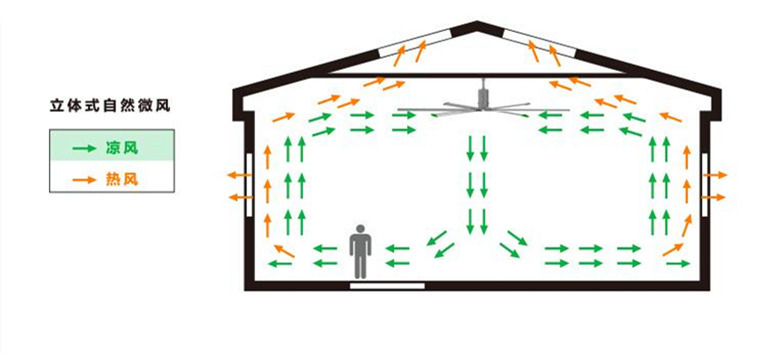

Briefly explain the principle of ventilation and cooling of industrial large fans: The cool concept of natural ventilation combined with modern aviation wing technology promotes a large amount of airflow to the ground and flows to both sides through the slow rotation of the 7.3 meters huge streamlined fan blade, resulting in a unique and efficient horizontal airflow layer. Silent airflow up to 20m in the center of the fan! The horizontal flow of air travels outwards in large quantities until it encounters side walls or other large obstacles, continuously generating a three-dimensional circulating wind.

Solution six: spray atomization ventilation cooling scheme

solution description:

Spray atomization cooling principle: outdoor space environment cooling system, can locally control the temperature of the large environment. Artificial fog cooling system emits water particles into the air, in the process of vaporization to absorb a large amount of heat in the surrounding environment, evaporative cooling to reduce the principle of ambient temperature, is an effective means of outdoor heat protection and cooling. Artificial fog space environment cooling principle for aerosol double flow, evaporation heat absorption principle, cooling terminal will be diameter in 1-10 microns of fog particles diffusion to the cooling area, in the process of diffusion continuous evaporation, and absorb a large amount of thermal energy in the area, scientific statistics of a kilogram of water excitation into a floating state of artificial fog, the effect obtained is equal to dissolving seven kilograms of ice, generally up to 6 ° C -10 ° C cooling effect, in extreme cases can be cooling amplitude of 14 ° C. Low operating costs, significant and rapid cooling effect. The effect of spray cooling is greatly affected by air humidity, and the higher the relative humidity, the worse the effect. Therefore, the effect of spray cooling for indoors is poor, especially for poor ventilation indoor spray cooling effect is even more limited.